Banana stickers have been a simple but effective form of advertising for decades. For brands, they provide instant recognition at very low cost. Collectors love them, and companies sometimes even use them for promotions or special editions.

However, there are challenges: each sticker has to be applied by hand, which is time-consuming and costly. On top of that, sustainability is becoming more important, and stickers made of plastic or paper with glue are not always welcome in a world moving towards zero packaging.

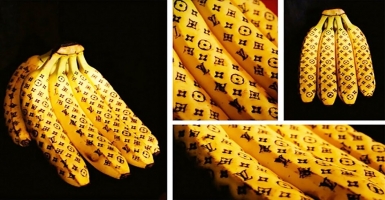

This is where Natural Branding (Laser Branding) comes in. With this technique, a laser gently removes pigments from the fruit’s skin, creating a permanent mark such as a logo, text, or even a QR code — without ink, glue, or packaging. The process is safe, fast, and environmentally friendly. Studies show that shelf life and taste remain unaffected.

Laser branding is already being used by retailers across Europe, particularly for organic products. Chains such as ICA in Sweden, REWE and Edeka in Germany, and Marks & Spencer in the UK have introduced laser-marked avocados, sweet potatoes, and even some citrus fruits. The Spanish company LaserFood and the German provider EcoMark are among the pioneers in developing and supplying this technology.

For standard bananas, stickers will probably remain for some time because they are cheap and flexible. But in the organic and premium segment, laser branding is likely to expand, driven by sustainability goals and modern marketing opportunities. It not only replaces the sticker but also allows for detailed traceability codes to be marked directly on the fruit.

For collectors, this means banana stickers may gradually become rarer — turning today’s labels into valuable historical pieces of fruit marketing.

Comments

Interesting news.

Interesting news. Congratulations!